2021

What works best to protect bilge wells and lines from sulphur?

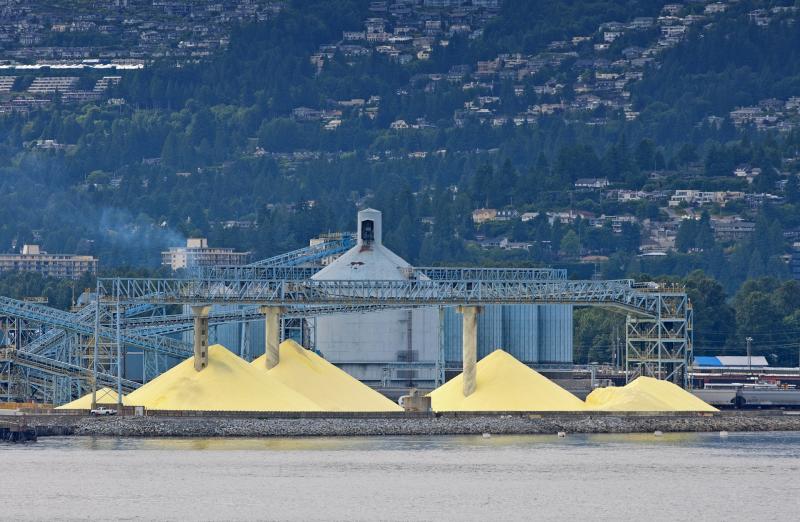

All forms of bulk sulfur, whether solid, lumps or grains, are corrosive when wet. And it is often wet right from the beginning of the loading process, having been exposed to rain on shore, or as a result of water sprays meant to keep sulfur dust--an environment pollutant-- to a minimum.

The IMO Code of Practice for Solid Bulk Cargoes (IMO BC Code) states: “Materials which present corrosive hazards of such intensity as to affect either human tissue or the ship’s structure should only be loaded after adequate precautions and protecting measures have been taken.”

As a result cargo holds are shielded as thoroughly as possible from the corrosive effects of sulfuric acid through protective coatings such as paint--which must be in good condition--and a hold block like RBM HoldBlock.

But bilge wells and bilge lines also need to be protected. Caustic soda flakes have been used but there are products available that do the job better. For example, RBM BilgeCoat is an alkaline solution used for the protection of bilge lines and bilge wells during sulphur voyages. It works by neutralizing acidic water. Crews find it easier to use and safer than caustic soda flakes. It is also safe for the environment.

RBM BilgeCoat works best to protects bilge wells and lines from sulphur

- Bilge protection against acidic water.

- Non harmful to the environment.

- Easier to use and safer than caustic soda flakes.

Approx. 15 litres of BilgeCoat solution is poured down each sounding pipe, in each hold, prior to loading sulphur and after each flushing of the bilges during the voyage. We recommend 1 jug per hold, per week.

Since 1999, RBM HoldSolutions® has been providing cargo ship holds protection against corrosive bulk materials such as sulphur, coal, petcoke, salts and fertilizers.